Couldn’t be simpler

Aluminium Façade Profiles

in anthracite TX

QCC PROFILES:

TOP QUALITY APPEARANCE.

OUTSTANDING PERFORMANCE.

Up to 35 years guarantee

Applications

Façade and gable cladding, wall cladding, parapet cladding, roof overhang cladding and extension cladding.

Safe material

All our panels consist of the aluminium alloy EN AW-3105 and are 1.0 mm thick. The accessory profiles consist of the same material. Both fulfill the requirements of fire protection classification A1 and are therefore non-combustible.

EN AW-3105

Surface finish

The surface finish on our panels consists of a colour coating applied in the ECCA coil coating process. This consists of two- or three-coat stove enamelling.

The coating is available in various qualities, such as polyvinyl fluoride (PVDF), polyester (PES), polyurethane polyamide (PUR-PA) and Duragloss 5000. All offer good to excellent corrosion- and UV-resistance. A protective coating is applied to the back of the panels (inside) which should not be exposed to the weather conditions.

Durability

- moisture-resistant

- weather-proof

- UV-resistant

- corrosion-resistant

- dimensionally stable

Top performance

- highly resilient

- good sound-proofing

- fire classification A1

- lightweight (only 4.1 kg/m2)

Sustainability

- 100% recyclable

- good heat protection

Care

- easy to clean

- no maintenance

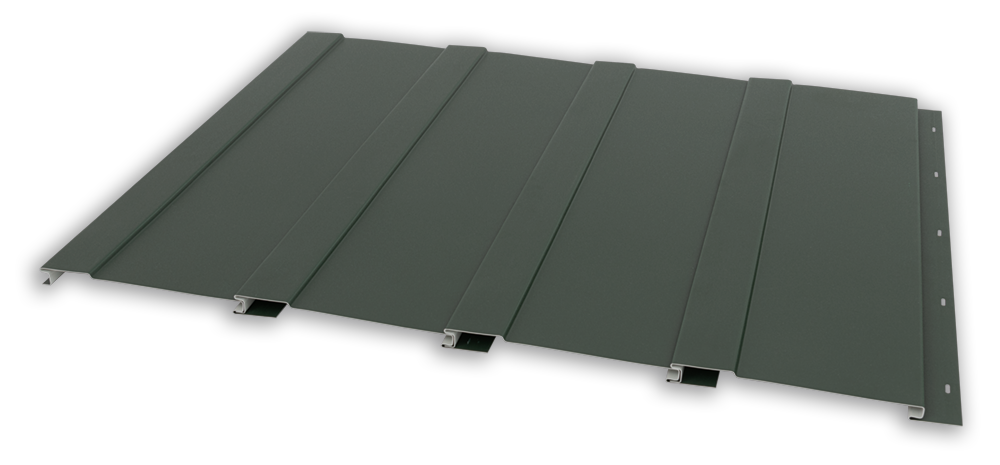

profile types

Horizontal and vertical laying pattern: four different panels

Joint panel flush-mounted (FP)

Joint width between 0 – 20 mm, horizontal and vertical laying pattern, coverage width 250 mm, thickness 1.0 mm

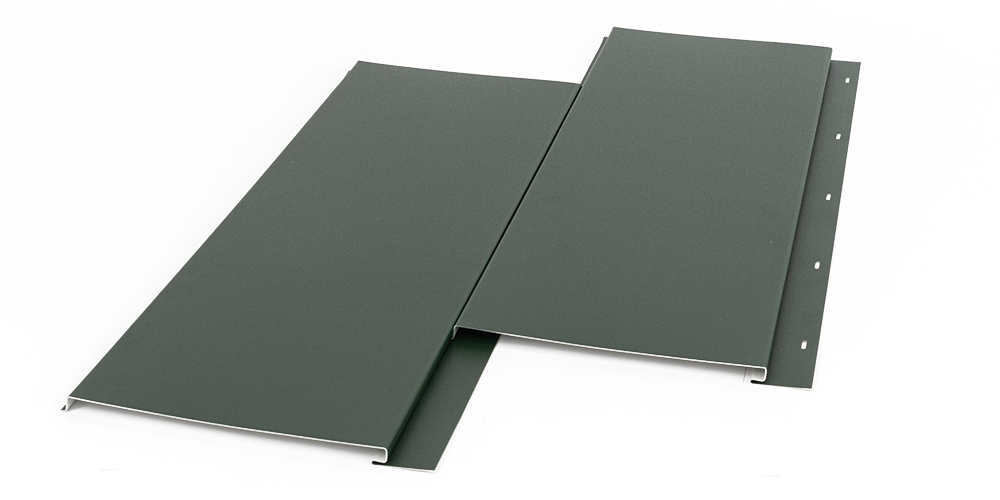

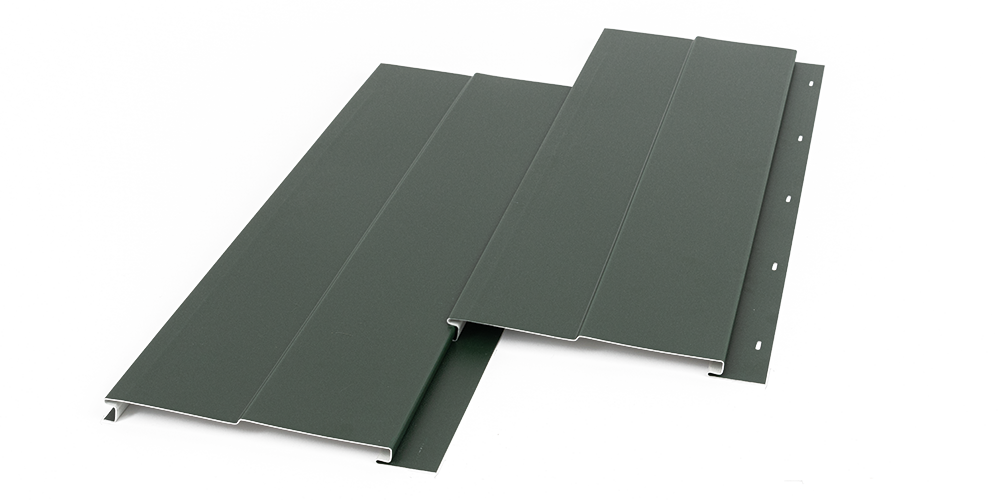

Sliding panel (SP)

Mainly horizontal laying pattern, vertical possible, coverage width 220 mm, thickness 1.0 mm

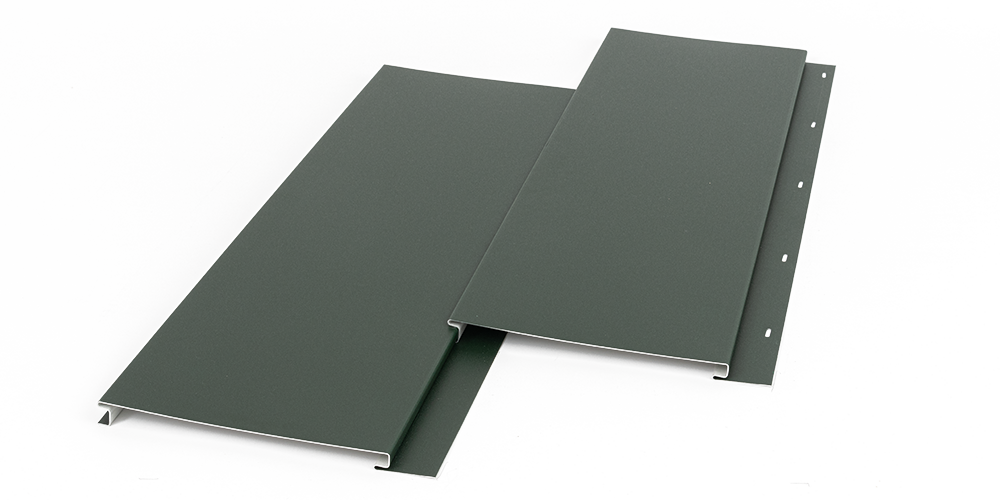

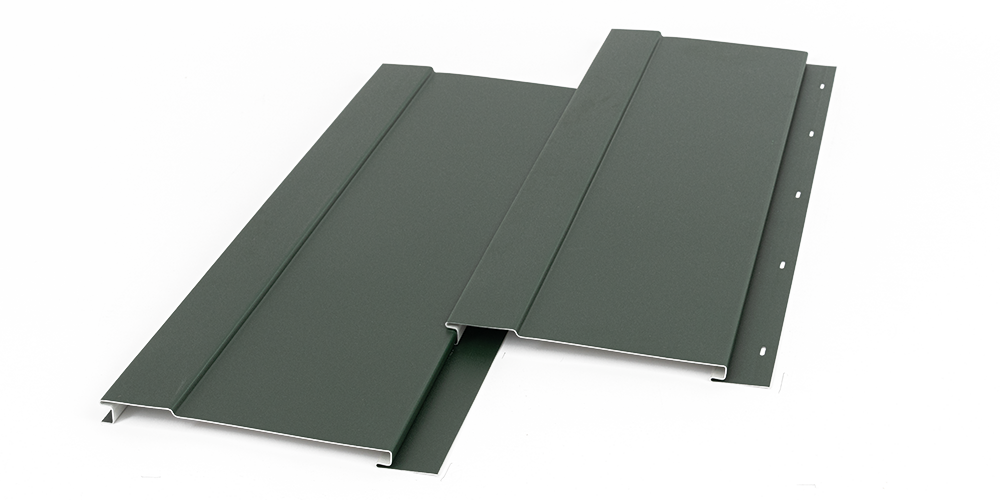

Sliding panel underpinned (SPU)

Mainly horizontal pattern, vertical possible, coverage width 220 mm, thickness 1.0 mm

Panel-on-panel cladding (BDP)

Horizontal and vertical laying pattern, coverage width 220 mm, thickness 1.0 mm

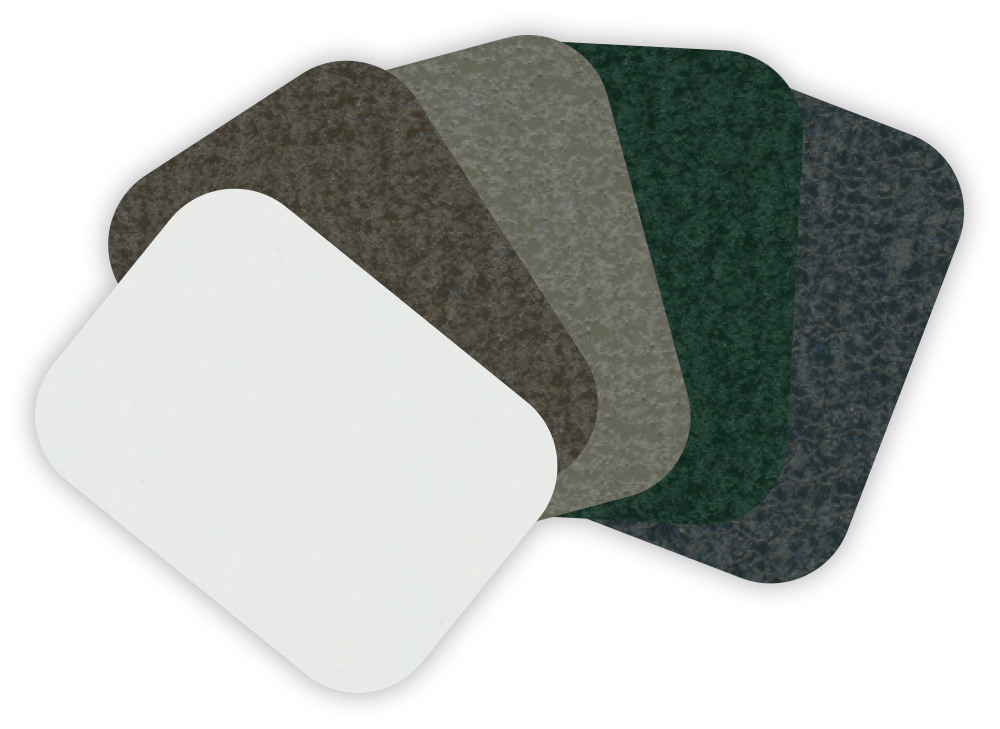

Colours

There’s always a matching colour: eight texture coatings (TX) and 3D coatings (3D)

Structures

Natural look: 3D wood texture in four trendy variations

No such thing as “can’t”

Accessory parts for façade profiles

No matter what kind of façade cladding you are looking for, we have exactly the right solution for you. You’re sure to find exactly what you need for your project among the many standard edging products. Otherwise, simply ask us for special individual edging.

You can take it for granted that special edging is possible. Simply ask us!

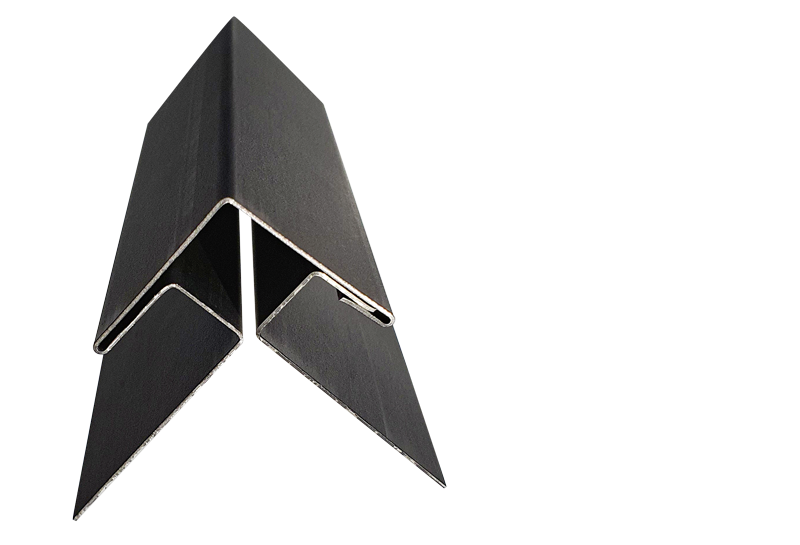

AE2

Two-part outer corner

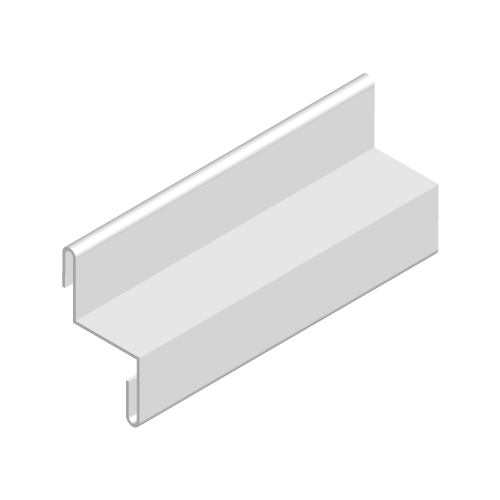

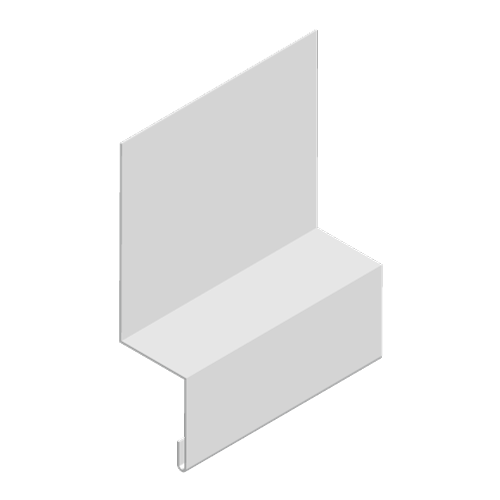

AP17

End profile

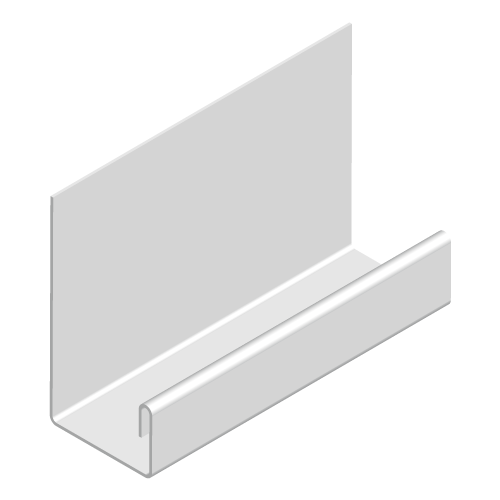

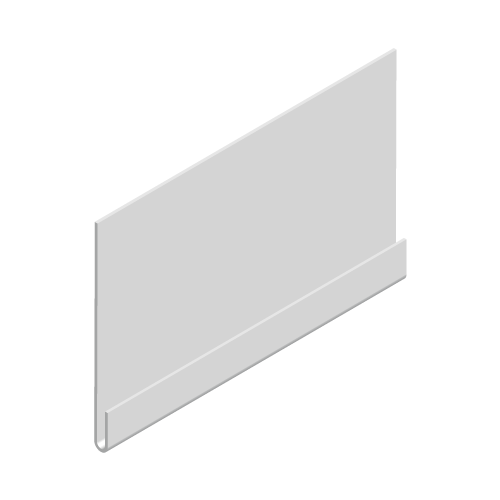

EP17

Push-in profile

EP45/60

Push-in profile

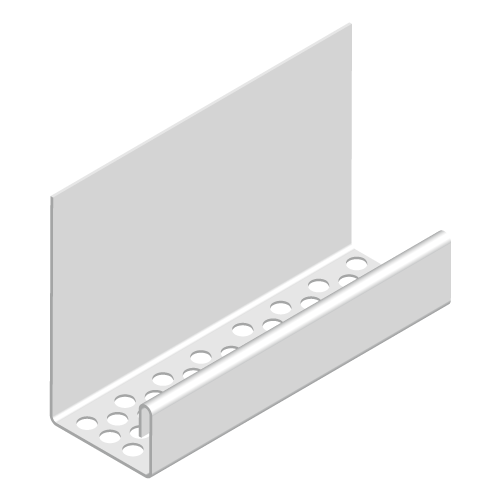

EPG17

Perforated push-in profile

GTP35

Storey separation profile

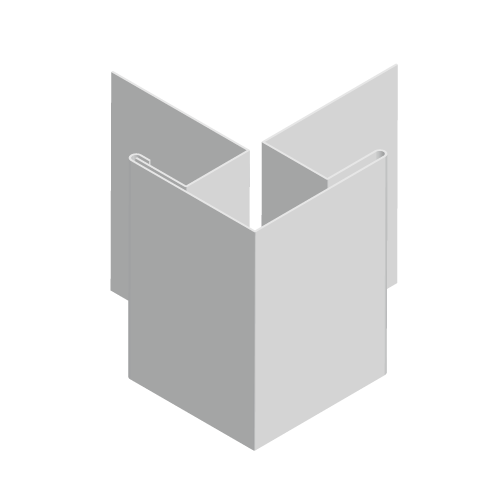

IE2

Two-part inner corner

KP

Clamping profile for connection panel

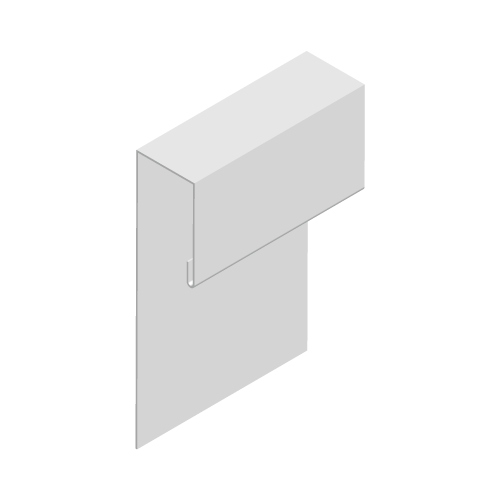

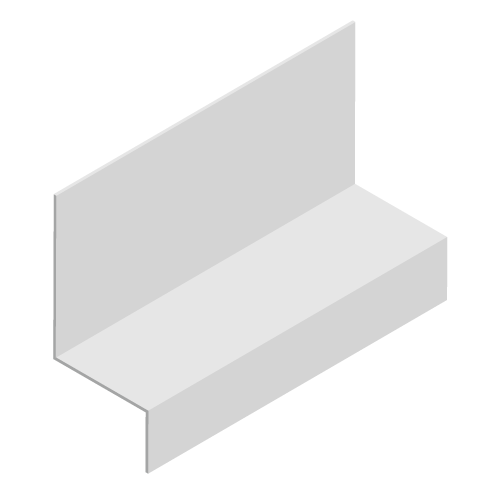

SP17

Starting profile

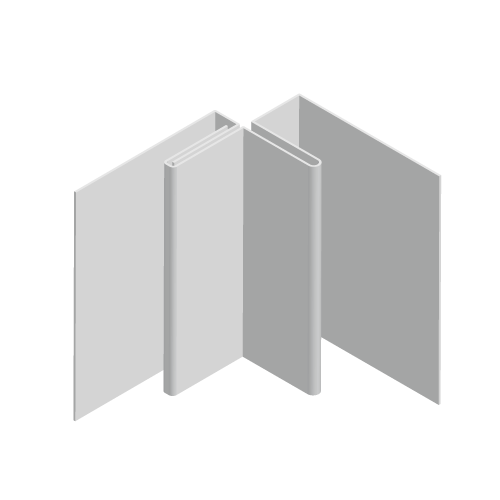

VP2

Two-part connecting profile

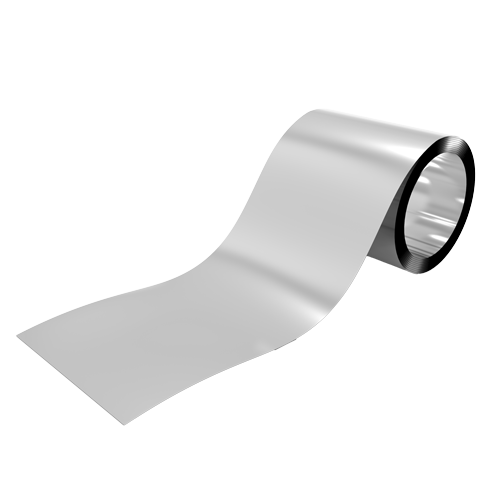

EB1000

Augmenting tape

1000 x 1.0 mm as needed

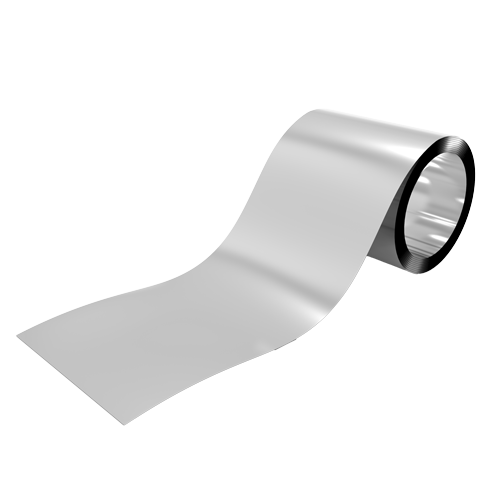

EB333

Augmenting tape

333 x 1.0 mm as needed

Instructions

Substructure

Safe installation and precise fastening requires a correctly aligned substructure made of lathing larger than 4 x 6 cm. The maximum lath spacing is 60 cm, with max. 20 cm to corners and edge strips. Counterlathing is necessary for vertical installation. The backing structure is usually protected by a water-proof vapour-permeable film!

Installation

Both horizontal and vertical installation of the panels is possible. Depending on the laying pattern, begin with the edge surrounds (EPG17/EP17/SP1) or start profiles. Install the panels. Allow sufficient space for elongation between the edge surrounds and the panels.

Use the screw (SB35) and the oblong holes to fasten the panels. Do not tighten the screw too tight. Please use the profiles AE2/IE2 for corners. The profiles VP2/GTP are suitable for façade extensions.

Rear ventilation

It is very important to allow for rear ventilation of the façade. This prevents condensation and protects the structure.

The ventilation openings at the bottom and top of the facade must measure min. 50 cm2 per 1 m wall length.

Cleaning and care

We recommend wiping the coated surface with water and a soft cloth. Add a pH-neutral household cleaner to the water to remove stubborn dirt.

Please do not use abrasive cleaning agents with coarse particles, acids or bases!

Storage

Store the panels in dry conditions on a flat surface. They may not be exposed to the weather and to direct sunlight while in packed state. Never process material that is faulty or has been damaged during transport. Mark it accordingly and send it back.

Delivery

The panels are delivered in easy-to-use packaging units. As a rule, one packaging unit consists of 10 panels 4000 mm long. Accessory profiles as needed.

All panels can be supplied at short notice!

Don’t hesitate to contact me!

I’ll be glad to help you select the panels and provide you with a non-binding offer free of charge.

Clemens Neumeister

Managing Director